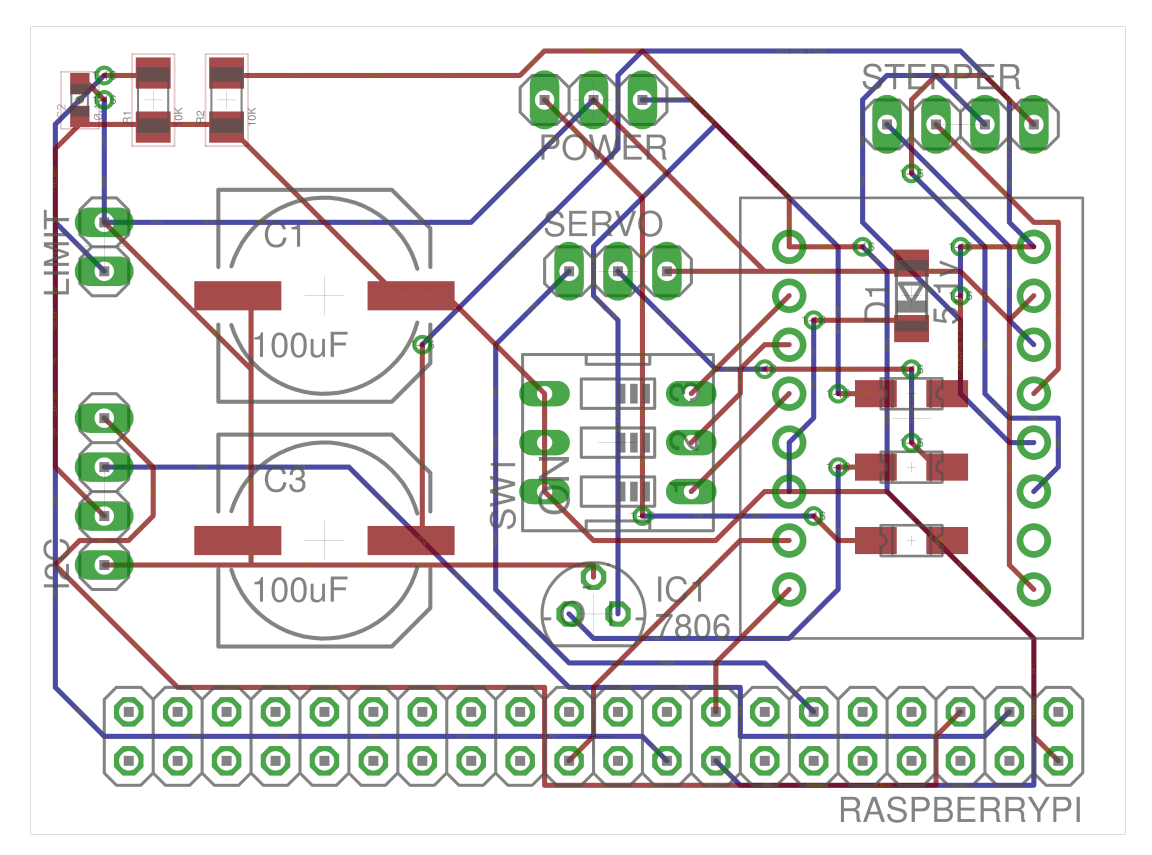

software. PCB printing with a 3D printer is now easier than before with the latest version of NanoDLP. One of the best ways to make a high-resolution PCB (circuit board) is to use a technique called Photoengraving. Your SLA 3D printer could easily print PCB boards using the same method. There are different ways to do this. But what we are dealing with in this article is constructing a printed circuit using a 3D printer with NanoDLP 3D-print software. Have you heard about it? So come on till the end to understand how to do it.

Is making things in different ways interesting for you? Join us: We use a NanoDLP SLA resin 3D printer.

The new dedicated feature for PCB printing on NanoDLP SLA 3D-print software helps you to print a PCB design in PNG and JPEG formats. It automatically fits the PCB and inverts the circuit board schema.

We offer some small tricks to improve the work result and enjoy the result at the end.

1. Firstly, design the PCB in the appropriate software. The output can be a .png or .jpeg file.

2. Cut a piece of copper according to the size of the PCB and clean it with acetone.

3. Then, a small amount of SLA resin is poured on the printed surface of the printer. The copper piece is gently placed on the resin.

4. Set the printer at the start point. The printer prints the first layer of plastic onto the copper. Only you need a single layer.

5. After this step, the PCB that you placed in a plastic container filled with ferric chloride.

6. After a while, the PCB is ready.

This method looks simple and works properly. You can use this method using the latest version of Nano DLP.

Tips and tricks for PCB printing with SLA printer

1- Clean the board with Scotch Brite rather than sandpaper. The sandpaper will scratch the copper. Remove the sharp edges of the copper board with sandpaper. After that, scrub the entire surface of the copper board in smooth and uniform lines. Do not move the hand in a circle or change direction.

2- We need electrical tape to fix the copper on the plate of the printer.

3- After finishing work, remove the resin with alcohol. The resin used in this method is photosensitive. The created resin layer is an acid-resist mask.

Why use the SLA NanoDLP 3D printer?

Compared to other methods, using NanoDLP to print PCBs is faster. Printing the PCB using FDM 3D printers may take a few days.

The resolution and the quality of work using an SLA printer are very high. And the result is very accurate. So you can print complex models. Of course, due to the small bed size of the SLA printer, this method is suitable for single-layer circuits.

Using SLA NanoDLP dashboard

At your printer NanoDLP web interface, from the top menu, select plates:

Then scroll the page; you will find the PCB Print button below:

By selecting the PCB Print button, you can see the following environment.

Choose a name for your plate. Upload the printed circuit modeling file in the desired format and select the Generate button.

For more information, you can check out the online guide about PCB printing using an SLA 3D printer.

Latest Posts

NanoDLP Software for SLS 3D Printers

One of the less known aspect of the NanoDLP is the ability to control both SLS and Laser SLA 3d printers. SLS is type of 3D printers create shapes by using laser to heat powders. Compare to SLA (Resin) printers quality is lower but additional support structure is not needed and high-end SLS machines use […]

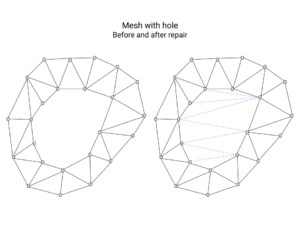

STL Mesh Repair

Technology Of Mesh Repair Tool NanoDLP Repair tool is developed using Golang language which makes it available on all platform including on your browser Simple interface Of Mesh Repair Tool We don’t ask you for any complex input. Just import your STL model and sit back until it’s repaired. Features Of Mesh Repair Tool Our […]

Web Browser-Based SLA 3D Printer Slicer

SLA 3D printer web browser based slicer rely on your browser resources to slice 3D files instead of Raspberry Pi (or other host SBCs)